News and innovations from Czechoslovak Group

The Czechoslovak Group (CSG) was the main partner of this year's IDET 2025 International Defence and Security Technology Fair. The group is one of the largest defence industry entities in Central Europe, with its offering covering almost all sectors of this segment. Its companies are also committed to innovation, new trends and opportunities, including the use of artificial intelligence. That is why we have prepared a special continuation of this program directly from the IDET studio with representatives of these companies and the group: Tomáš Mohapl, CEO of TDV, Jakub Čmuchálek, Sales Director of MSM Group, Jan Mikulecký, CEO of Retia, and Pavel Jurečka, Executive Director of VÝVOJ Martin.

Video: News and innovations from CSG companies / CZ DEFENCE

Tatra Defence Vehicle (TDV) has officially unveiled its new Pandur 8×8 EVO armored vehicle, which was the main exhibit at this year's trade fair. The development of this vehicle builds on the experience gained from the previous generation of Pandur 8x8 vehicles, but significantly expands on it with new protection and digitalization features. These are based not only on the current requirements of the Czech Army, but also on lessons learned from the war in Ukraine. “It was the culmination of a great effort by our company to put together such a beautiful vehicle. It was a great joy and a great relief. I think we have succeeded,” said TDV CEO Tomáš Mohapl at the launch ceremony for the new Pandur 8×8 EVO.

According to Mohapl, the new Pandur is a direct evolution of the Pandur II 8x8, building on its proven design. However, the developers have integrated a wealth of knowledge from current conflicts into the design. “We took advantage of the good features of the Pandur platform, but at the same time we implemented knowledge gained from the battlefield – for example, from Ukraine – or from the current needs of the army,” he explained. The vehicle's protection has also undergone fundamental changes. "We have increased both its mine and ballistic resistance. However, we did not rely solely on state-of-the-art armor – we also equipped the vehicle with an active protection system," he added. The integrated active elements include, for example, the Iron Fist system, capable of eliminating drones, anti-tank missiles, RPGs, and other threats. Another important part of the modernization is the new weapon station. "It integrates all the components mentioned, including air defense capabilities. At longer ranges, the anti-drone gun can be used, and at shorter ranges, the Iron Fist system," explained Mohapl. The main armament consists of a 30mm cannon, supplemented by a 7.62mm coaxial machine gun and a pair of anti-tank missiles with extended range. The weapon station is also equipped with advanced sensors, including a laser detection system. These sensors are linked to a sophisticated camera system and artificial intelligence algorithms. “Artificial intelligence is integrated into the layers of the camera system to recognize objects and assess whether they pose a threat. At the same time, it provides data for autonomous control and simplifies the categorization of targets and objects in the vicinity of the vehicle,” described the CEO.

According to the manufacturer, the Pandur 8×8 EVO is a Czech product, but it was developed in international cooperation. “The vehicle is not 100% Czech. We say that it was developed and manufactured in the Czech Republic, but we cooperate with key partners, such as Israeli companies. Such a sophisticated vehicle cannot be built in just one country, such as the Czech Republic,” explained Mohapl, adding that cooperation with renowned foreign partners is an advantage for TDV.

The European defense industry is facing unprecedented demand for ammunition and explosives. MSM Group, part of the Czechoslovak Group holding, is responding to this situation with massive investments and expansion of production capacities across Europe. Jakub Čmuchálek, Commercial Director of MSM Export s.r.o., emphasizes that the group's goal is not only to meet current needs, but above all to strengthen European strategic independence. One of MSM's key objectives is to restore European capacity for the production of trinitrotoluene (TNT), a basic explosive for artillery and other ammunition. “Currently, the only TNT manufacturer in Europe is a company in Poland. This is not ideal – as they say, it's not good to put all your eggs in one basket,” said Čmuchálek. “That is why we consider the resumption of TNT production to be important not only for our CSG group, but above all for the entire European defense industry.”

In recent months, MSM Group has made several strategic acquisitions that expand its capacity and technological portfolio. One of the key acquisitions was the purchase of a nitrocellulose and other chemicals production plant in Rottweil am Neckar, Germany. “We don't want to build everything from scratch. Buying an existing plant with a history is a much more efficient way than building a new factory on a greenfield site,” explained Čmuchálek. Another reason is the complex legislation. “In Europe today, it is very difficult to obtain permits for the construction of new chemical or pyrotechnic production facilities. Obtaining permits and completing processes is a long-term endeavor, which is why the acquisition of existing companies makes sense,” he added. The group's long-term strategy is to gain control over the entire production chain. “We want to manufacture from A to Z – from raw materials through semi-finished products to final products. We are innovating existing plants, increasing capacity, and investing in new technologies,” confirmed the sales director of MSM Export.

The main focus remains on the production of large-caliber ammunition, especially 155 mm artillery shells, which are NATO standard. “Current demand shows that this trend is far from over. Increasing capacity is not a matter of months, but years. Moreover, I believe that there will also be a change in doctrine – countries will have to reassess their stockpiles and preparedness for crisis scenarios,” said Čmuchálek. An interesting feature of MSM Group's approach is the retention of two different ammunition filling technologies – casting and so-called screw feeding. “We will keep both technologies because each has its advantages,” explained Čmuchálek. “Screw feeding provides better control over density and is essentially a Czechoslovak invention. Casting, on the other hand, is advantageous for drone warheads, for example.”

The Pardubice-based company Retia, part of the Czechoslovak Group holding, has long been a leader in radar and communications technologies. At this year's defense technology fair, it presented major innovations in command and control systems and demonstrated how artificial intelligence (AI) can be used in a realistic and meaningful way on the modern battlefield. “Artificial intelligence is often an overused term, a buzzword. But we use it in a targeted way – in the form of neural networks that we teach to recognize situations. Together with Axon, we have developed a system called Situational Awareness,” explains Jan Mikulecký, CEO of Retia. According to him, this system is of fundamental importance for decision-making processes on the battlefield – whether in the army, the police, or other security forces. “Based on data from sensors and experience from past events, the system alerts users to potentially dangerous situations. For example, it recognizes that a certain pattern of behavior may indicate an imminent threat,” Mikulecký describes. The system has been tested not only in the Czech Republic but also in real conflict conditions. “We tested it in Gaza, for example. There, we taught neural networks to recognize specific types of threats. We then transferred this experience to the new Pandur 8×8 EVO, where the system is now fully implemented,” he adds.

Retia is also developing a new Air Mission Command & Control system, which, according to Mikulecký, is of fundamental importance for the future capabilities of the Czech Army. "In the Czech Republic, we do not currently have fully integrated air mission control, and with the arrival of the F-35, this will be necessary. We are therefore working on a system that will link different levels of command – from ground forces to air forces. This means that the system will collect data from all layers – land, air, and airborne – and distribute it back to command levels and individual units in the field," he explains. At the same time, he points out the ethical issues associated with the use of AI in command systems. Where does the machine end and human decision-making begin? "Humans can enter the decision-making process at any time – but this automatically slows down the flow of information. If we want a quick response, for example to an airspace violation, it is faster to leave the decision to the system. For example, radar detects a threat and the information goes immediately to the command system, which automatically activates the base, for example in Čáslav with F-35s, and sends a response. But the moment lethal force is to be used, humans enter the process," Mikulecký describes the ethics of decision-making.

With its innovations, Retia contributes not only to greater command efficiency, but also to the ability of security forces to respond quickly, accurately, and in an informed manner. Artificial intelligence is not an end in itself here, but rather a tool that supports human decision-making and provides a real-time overview of the situation. “Our goal is not to replace people, but to give them the tools to make decisions faster, safer, and with better information. That's what our entire approach to Command & Control and situational awareness is all about,” concludes Jan Mikulecký.

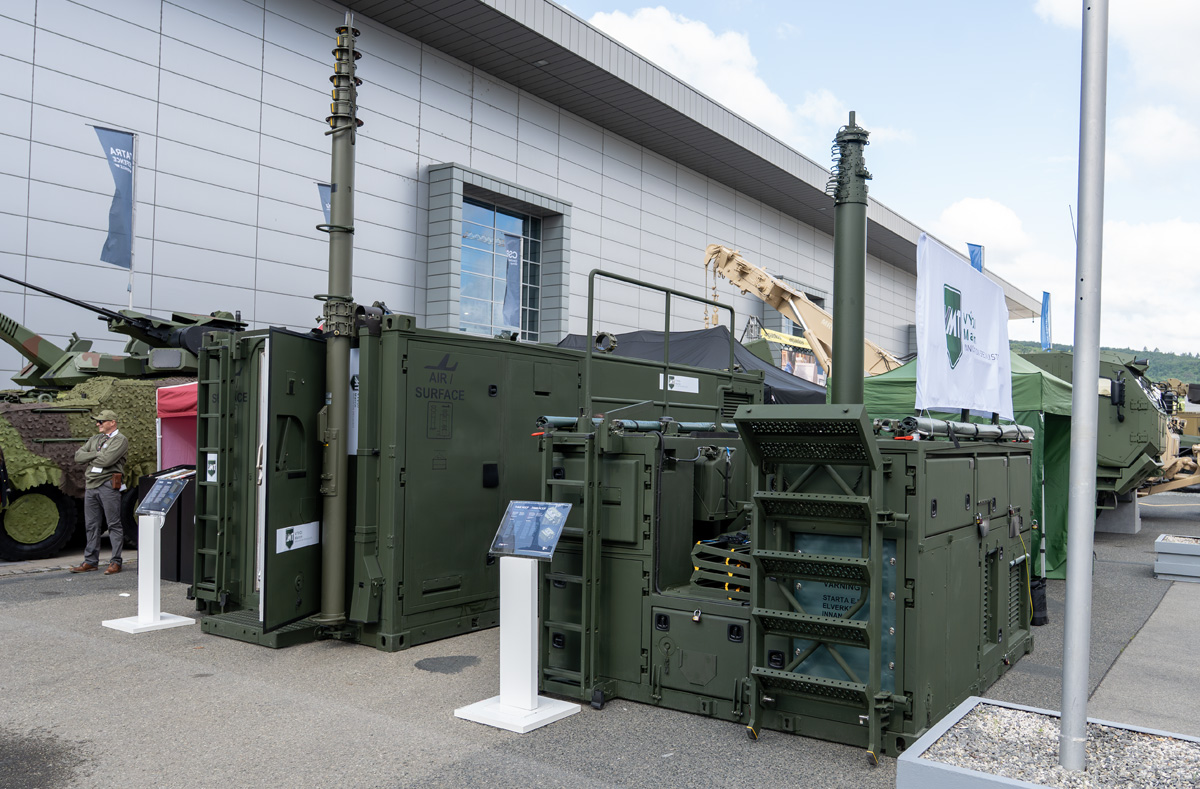

At this year's IDET trade fair, Slovak company VÝVOJ Martin presented one of the most interesting examples of contemporary military technology – sophisticated defense containers with a high degree of automation, low observability, and the ability to operate independently in demanding conditions. The company is also embracing the trends of the modern battlefield – an emphasis on mobility, digitalization, and the protection of human life. “Our main product is special containers, which account for more than 80% of our production. These are mainly C2 containers designed for control, command, communication, and medical purposes in military conditions,” explains CEO Pavel Jurečka.

The purpose of these containers is not only to provide functional facilities for various military activities, but above all to protect the crew and prevent detection by electronic reconnaissance equipment. “The containers do not emit heat or electromagnetic radiation. Using a combination of passive elements, such as a Faraday cage, and active special filters, we create an environment that is practically undetectable,” Jurečka explains. He adds that the design of some filters resembles honeycombs, whose task is to “dissipate the signal” so that it cannot be detected externally. Interestingly, in recent years, the company has been moving away from ballistic protection based on lessons learned from the ongoing war in Ukraine. “Today, it is becoming apparent that armored vehicles are easy targets. The advantage is to be as invisible as possible. Our containers can be placed far behind the front lines, and their main protection is that the enemy cannot find them,” says Jurečka.

VÝVOJ Martin also places great emphasis on unattended operation and autonomy. This year, the company unveiled its first fully automated unmanned container. “The container can be controlled remotely from headquarters – for example, from the capital of another country. Or it contains autonomous elements – it collects data on the weather and the environment and, based on this, evaluates the next steps itself or requests instructions from the commander,” explains Jurečka.

According to him, it is not enough to simply manufacture a container – the real added value lies in its internal technological equipment, which is often tailored to the specific customer. "Many companies can weld a container. However, we focus on the development and integration of technologies according to the requirements of the armed forces. These are often classified systems – customers do not want them to be discussed," he adds. For this reason, VÝVOJ Martin containers are built as multi-level security spaces with controlled access. They contain separate zones for working with classified information, including the so-called red and black lines.

The company currently plans to produce 60 of these special containers per year. Production is custom-made, both in terms of internal equipment and adaptation to the specific logistical requirements of individual armies.